What Is Letterpress?

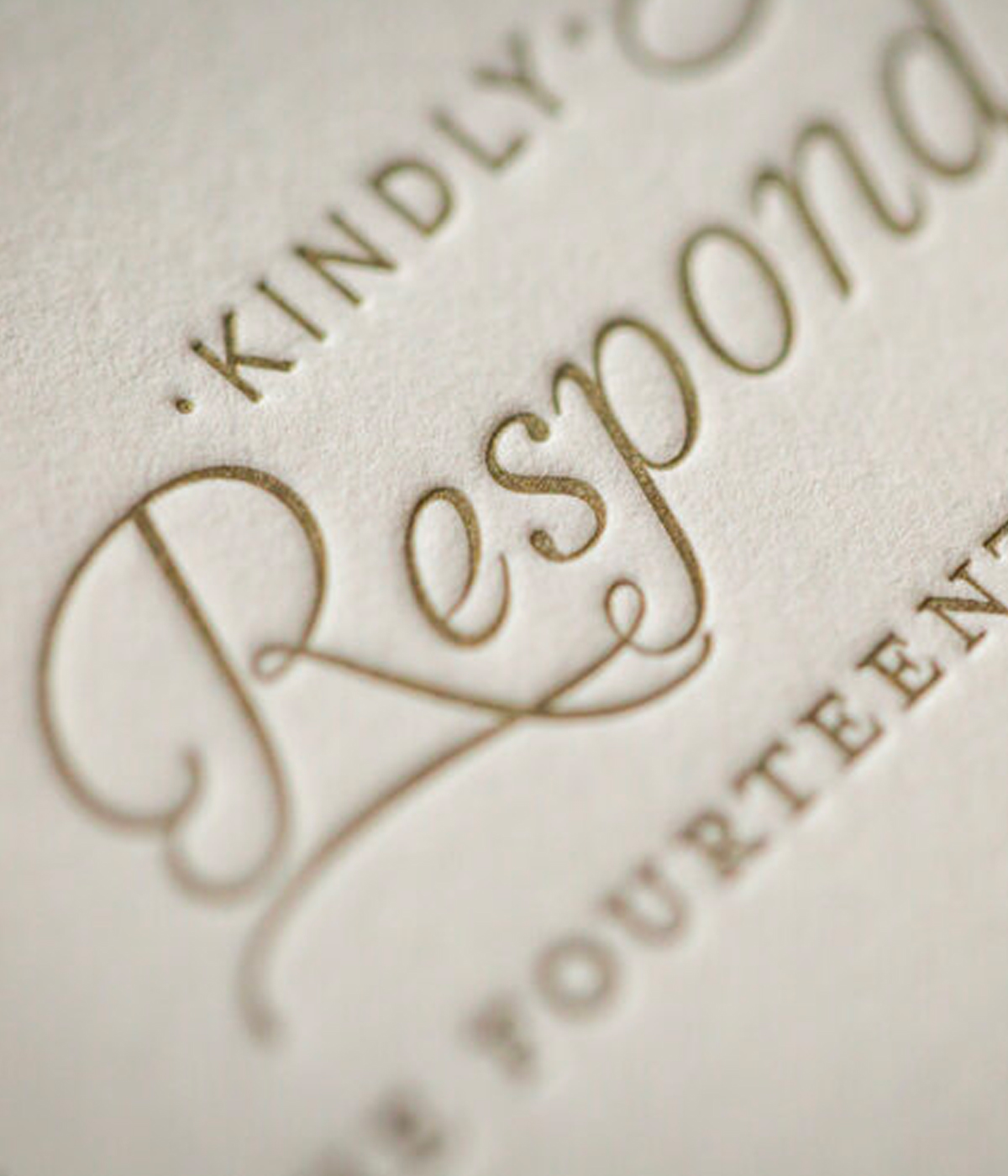

It’s simply one of the most beautiful ways to print.

It’s one of the oldest forms of printing and remained the primary way to print until the 20th century. Yet, through the advancement of offset and digital printing, letterpress has survived, liberated by artists and designers, and has been revived as a craft.

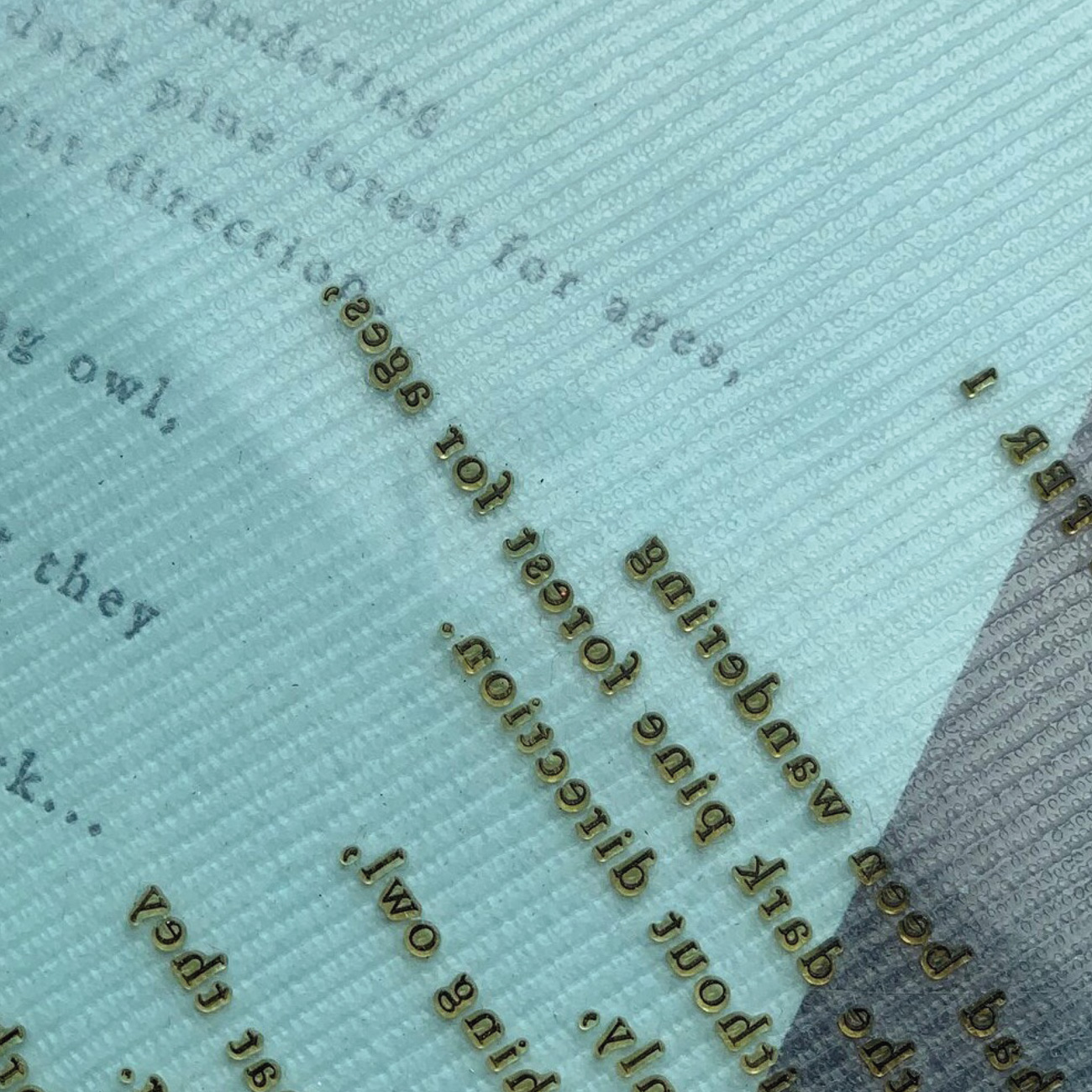

Inked surfaces are pressed into paper, leaving a textured impression. In previous years, it was moveable type. Today, we use photopolymer plates to create custom designs.

The only way to get that good impression is with a big, heavy printing press. Our oldest presses date back to the early 1900s. Every day in our shop we use Heidelberg Windmills from the 1950s.

For each color of a design, a printing plate is made, the press is set up and the paper is run through the press—one piece at a time. The more pieces you print, the less each piece will cost.

Unmatched Craftsmanship

In an industry that has been around for hundreds of years, relatively little has changed in the way letterpress printing is produced. It takes people, skilled hands, a creative vision and patience. This is what makes it so special.

There Are No Shortcuts

We certainly like to challenge the norm around here, but these are the simple truths of letterpress:

- A printing or foil plate must be made for every color of the design, even blind impression.

- A printing press must be set up to print by a skilled craftsperson. This includes, but is not limited to, inking, registration, and adjusting impressions.

- Each piece is printed one at a time, one color at a time – no matter what.

Let Us Help You Get Started

We’re sure you’ll be happy with your finished product––and we’ll be happy to help you along the way. Here are a few things to consider when thinking about your project. We’ll help you make the right decisions in order to give you the most for your investment.

.01

Multiple colors will always, always (always) be more expensive than one color. For every color in a design, a unique printing plate is produced, the printing press is set up, the project is run, and then the press is cleaned, re-inked, and so forth – no matter what.

How we can help you reduce cost:

- Choosing the right number of colors for your project

- Suggesting halftones or overlapping colors

- Coordinate colors across different designs

Some things to keep in mind (these variables typically stay the same):

- The cost of printing plates and foil dies, and the fact that every element of a design that adds another color, needs another printing plate and press run.

- Blind impression counts as a color. You’ll save cost on ink mixing, but the rest of the process is the same.

.02

Letterpress ink (part of what gives our shop that old-timey good feeling smell of bygone days) is semi-transparent. This means that lighter colored inks will not appear on darker papers. They just end up being a way less exciting, slightly muddy, tonal shift of the paper color. Black, or metallic inks (most commonly gold and silver) are the only inks that will appear on dark paper, and while the metallic inks look really cool for some projects, for others they just don’t cut it. For a shiny look, or light colors that really pop against a dark background we can suggest the right foil color for you.

.03

Sometimes you need it, sometimes you don’t. Sometimes you want it, but if you are trying to stay within a budget, sticking to one-sided printing is something we always recommend. The rules are the same as with multiple colors (more colors = more plates and setup).

Most of the time when printing double-sided, we recommend printing on two separate pieces of paper and then duplexing (gluing) them together. This allows for the maximum impression on each side while avoiding show-through. It also allows us to mix paper colors and weights.

Duplexed paper is not required for double-sided printing. We are happy to walk you through the pros and cons of using it for your project.

.04

Most of the time it’s worth the investment, especially for repeat projects (it’s a one-time cost). However, if you have a small project and not a whole lot of wiggle room in your budget, it’s best to consider common shapes and sizes that don’t require a custom die.

.05

Common elements are especially helpful on business card projects. We can print multiple employee names at once by ganging them up on a sheet. If a design is multi-colored, but one or more of those colors is a common design element among the employees, you will save on plates, press set up, and time.

.06

The higher the quantity, the lower the cost per piece. This is because plate cost, press set up, etc. is the same for 1 piece as it is 1,000. Especially if you plan to order the same project again in the future, it’s less expensive to order bigger batches at once.

Recent Posts

SEE ALL BLOG POSTS

Wedding Planning During the Pandemic

Planning a wedding during the pandemic? We've got advice, and more importantly, we've got your back. We're ready and willing to help.

Read More

Don’t Get Hung Up On Hang Tags, Go Letterpress

Hang tags, can be a statement about quality and care. Boost your product appeal with a simple packaging punch.

Read More